NEED HELP?

(714) 891-0008

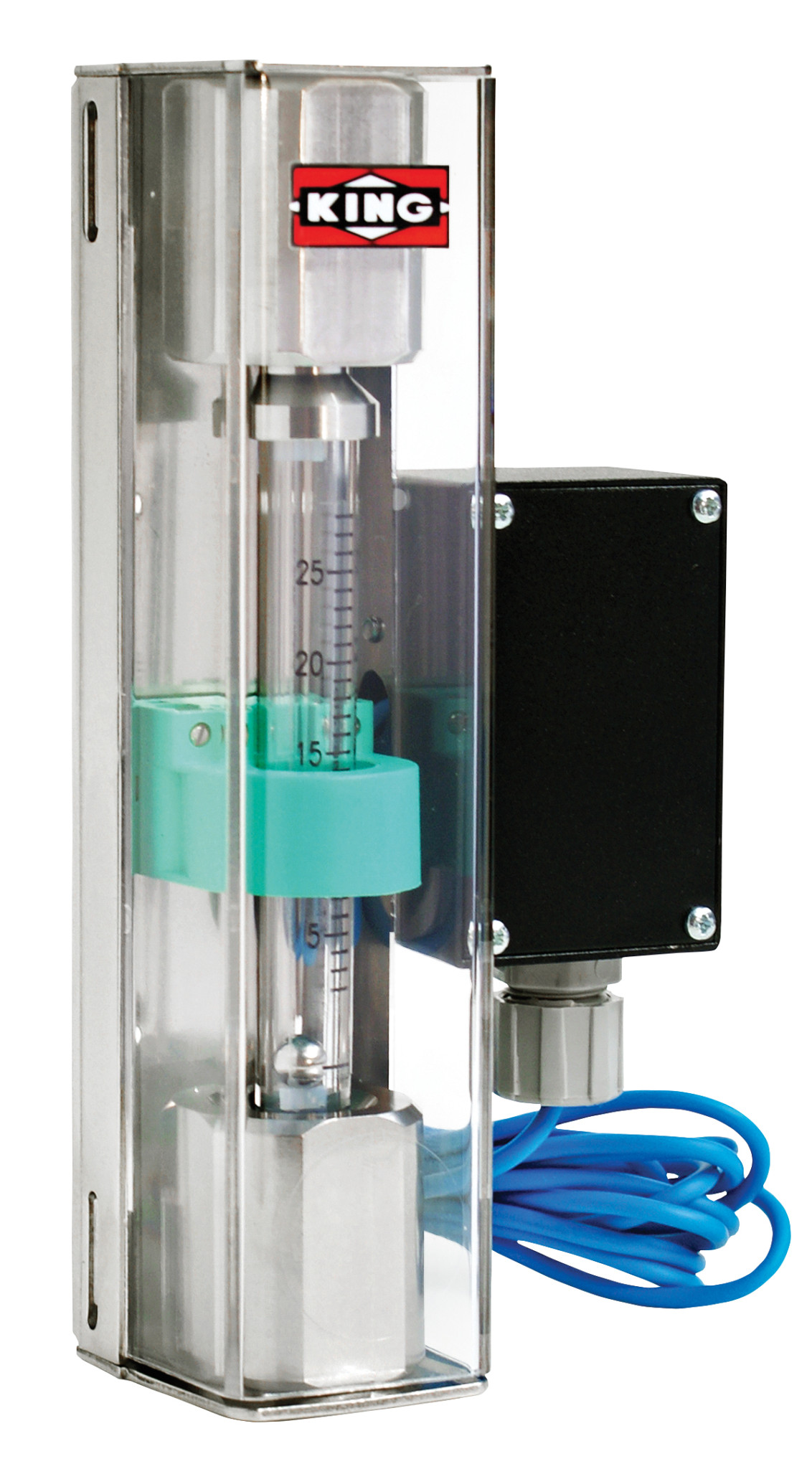

7440 Series - Glass Tube Flowmeters

Based on our proven panel-mountable 7430, we offer the vertically-connected 7440 with the same scale lengths, flow rates, and cost-effective performance for low-flow applications such as purge metering and chemical dosing.

DESCRIPTION

| Metering Tube | Borosilicate Kinglass |

| Internal Components | 316L stainless steel, black glass, sapphire, Carboloy, tantalum |

| Fitting Material | 316L SS |

| Optional: PVDF | |

| Inlet/Outlet Fittings | 1/4” FNPT, vertical |

| O-Ring | Standard: Viton® |

| Optional: Buna N, EPR, Kalrez® | |

PERFORMANCE

| Capacities | Water | 0.56 to 1,800 cc/min |

| Air | 54 to 70,000 cc/min | |

| Scale | 65 mm, 150 mm Direct reading, detachable | |

| Accuracy | ± 6% of full scale flow, 65 mm | |

| ± 4% of full scale flow, 150 mm | ||

| Turndown | 10:1 | |

| Repeatability | 1% | |

| Maximum Temperature | ||

| 316L SS fittings | Gases | 250° F (121° C) |

| Liquids | 200° F (93° C) | |

| PVDF fittings | Gases & Liquids | 200° F (93° C) |

| Maximum Pressure | 316L SS fittings | 200 psig |

| PVDF fittings | 150 psig | |

| Ambient Temperature | 33° F to 125° F (1° C to 52° C) | |

OPTIONS

| Alarm | Fiber-Optic or Inductive Ring Sensor | |

| Certified Calibrations | Conform to ISA RP 16.6 | |

| Scales | Any volumetric unit | |

| High Temperature | Ambient 250°F | |

SPECIFICATIONS

| 65MM Scale Flow Ranges | |||||||

| Tube Number |

Float Material |

Air (STP) | Water (70° F) | ||||

| CC/MIN | SCFH | SLPH | CC/MIN | GPH | LPH | ||

| 1-02-G-021 | Glass | 66 | .14 | 4.0 | 0.72 | .011 | .042 |

| Sapphire | 105 | .22 | 6.2 | 1.3 | .021 | .078 | |

| Stainless Steel | 200 | .42 | 12.0 | 3.3 | .052 | .190 | |

| Carboloy | 340 | .70 | 20.0 | 7.0 | .110 | .420 | |

| Tantalum | 350 | .74 | 21.0 | 7.8 | .125 | .460 | |

| 1-03-G-041 | Glass | 76 | .16 | 4.6 | 1.15 | .018 | .068 |

| Sapphire | 120 | .25 | 7.2 | 2.10 | .032 | .125 | |

| Stainless Steel | 230 | .50 | 14.0 | 4.20 | .068 | .260 | |

| Carboloy | 400 | .85 | 24.0 | 9.00 | .145 | .560 | |

| Tantalum | 440 | .90 | 26.0 | 10.00 | .165 | .620 | |

| 1-08-G-061 | Glass | 525 | 1.1 | 31 | 9.0 | .14 | .54 |

| Sapphire | 700 | 1.5 | 42 | 15.5 | .24 | .95 | |

| Stainless Steel | 1130 | 2.4 | 68 | 29.0 | .46 | 1.70 | |

| Carboloy | 1600 | 3.4 | 95 | 46.0 | .72 | 2.80 | |

| Tantalum | 1700 | 3.6 | 100 | 50.0 | .78 | 3.00 | |

| 1-23-G-081 | Glass | 2000 | 4.4 | 120 | 44 | .70 | 2.6 |

| Sapphire | 2600 | 5.4 | 150 | 68 | 1.05 | 4.0 | |

| Stainless Steel | 3800 | 8.2 | 230 | 110 | 1.70 | 6.6 | |

| Carboloy | 5600 | 12.0 | 340 | 170 | 2.70 | 10.5 | |

| Tantalum | 6000 | 13.0 | 360 | 180 | 2.90 | 11 | |

| 2-14-G-021 | Glass | 6800 | 14.5 | 400 | 160 | 2.6 | 9.5 |

| Sapphire | 9200 | 19.5 | 540 | 240 | 3.8 | 14 | |

| Stainless Steel | 13000 | 28.0 | 800 | 400 | 6.2 | 24 | |

| Carboloy | 19000 | 40.0 | 1100 | 600 | 9.5 | 36 | |

| Tantalum | 20000 | 42.0 | 1200 | 640 | 10.0 | 38 | |

| 2-34-G-041 | Glass | 19000 | 40.0 | 1150 | 520 | 8.25 | 31 |

| Sapphire | 25000 | 52.0 | 1500 | 740 | 11.50 | 44 | |

| Stainless Steel | 42500 | 90.0 | 2550 | 1200 | 19.00 | 72 | |

| Carboloy | 60000 | 125.0 | 3600 | 1700 | 27.00 | 105 | |

| Tantalum | 70000 | 145.0 | 4200 | 1800 | 29.00 | 110 | |

| 150 MM Scale Flow Ranges | |||||||

| Tube Number |

Float Material |

Air (STP) | Water (70° F) | ||||

| CC/MIN | SCFH | SLPH | CC/MIN | GPH | LPH | ||

| 1-03-G-022 | Glass | 54 | .114 | 3.2 | .56 | .0088 | .033 |

| Sapphire | 82 | .175 | 4.9 | 1.04 | .0160 | .062 | |

| Stainless Steel | 160 | .340 | 9.8 | 2.25 | .0350 | .135 | |

| Carboloy | 280 | .580 | 16.5 | 5.00 | .0780 | .300 | |

| Tantalum | 300 | .620 | 17.5 | 5.20 | .0840 | .320 | |

| 1-04-G-042 | Glass | 106 | .225 | 6.4 | 1.24 | .0195 | .074 |

| Sapphire | 165 | .35 | 10.0 | 2.35 | .0380 | .145 | |

| Stainless Steel | 320 | .68 | 19.0 | 5.60 | .0900 | .340 | |

| Carboloy | 540 | 1.14 | 32.0 | 12.4 | .1950 | .740 | |

| Tantalum | 580 | 1.24 | 35.0 | 13.5 | .2100 | .820 | |

| 1-07-G-062 | Glass | 350 | .74 | 21.0 | 4.7 | .074 | .28 |

| Sapphire | 500 | 1.06 | 30.0 | 10.0 | .160 | .60 | |

| Stainless Steel | 820 | 1.75 | 50.0 | 20.5 | .330 | 1.25 | |

| Carboloy | 1250 | 2.60 | 76.0 | 34.0 | .540 | 2.05 | |

| Tantalum | 1350 | 2.90 | 80.0 | 36.0 | .560 | 2.15 | |

| 1-11-G-082 | Glass | 850 | 1.8 | 50 | 16.5 | .26 | 1.0 |

| Sapphire | 1100 | 2.3 | 66 | 27.0 | .42 | 1.6 | |

| Stainless Steel | 1600 | 3.4 | 100 | 46.0 | .72 | 2.7 | |

| Carboloy | 2300 | 4.9 | 140 | 72.0 | 1.15 | 4.4 | |

| Tantalum | 2450 | 5.2 | 155 | 80.0 | 1.25 | 4.8 | |

| 1-27-G-102 | Glass | 2150 | 4.6 | 130 | 52 | .84 | 3.1 |

| Sapphire | 2800 | 6.0 | 170 | 78 | 1.24 | 4.7 | |

| Stainless Steel | 4400 | 9.2 | 260 | 130 | 2.05 | 7.8 | |

| Carboloy | 6200 | 13.5 | 380 | 205 | 3.20 | 12.5 | |

| Tantalum | 6750 | 14.0 | 400 | 210 | 3.30 | 12.5 | |

| 2-09-G-002 | Glass | 3800 | 8.2 | 230 | 86 | 1.35 | 5.2 |

| Sapphire | 5000 | 10.6 | 300.0 | 130 | 2.05 | 7.8 | |

| Stainless Steel | 7500 | 16.0 | 450 | 220 | 3.40 | 13.0 | |

| Carboloy | 10600 | 22.5 | 640 | 330 | 5.20 | 20.0 | |

| Tantalum | 11500 | 24.0 | 680 | 360 | 5.60 | 21.5 | |

| 2-17-G-022 | Glass | 9000 | 19.0 | 540 | 215 | 3.40 | 13.0 |

| Sapphire | 11400 | 24.5 | 700 | 320 | 5.00 | 19.0 | |

| Stainless Steel | 17000 | 36.0 | 1000 | 520 | 8.20 | 31.0 | |

| Carboloy | 24000 | 50.0 | 1450 | 760 | 12.2 | 46.0 | |

| Tantalum | 25000 | 54.0 | 1500 | 820 | 13.0 | 49.0 | |

| 2-32-G-042 | Glass | 20500 | 43.0 | 1220 | 470 | 7.5 | 28.0 |

| Sapphire | 26000 | 56.0 | 1550 | 700 | 11.0 | 42.0 | |

| Stainless Steel | 38000 | 82.0 | 2300 | 1120 | 18.0 | 68.0 | |

| Carboloy | 54000 | 116.0 | 3300 | 1650 | 26.0 | 100.0 | |

| Tantalum | 60000 | 125.0 | 3500 | 1750 | 28.0 | 106.0 | |

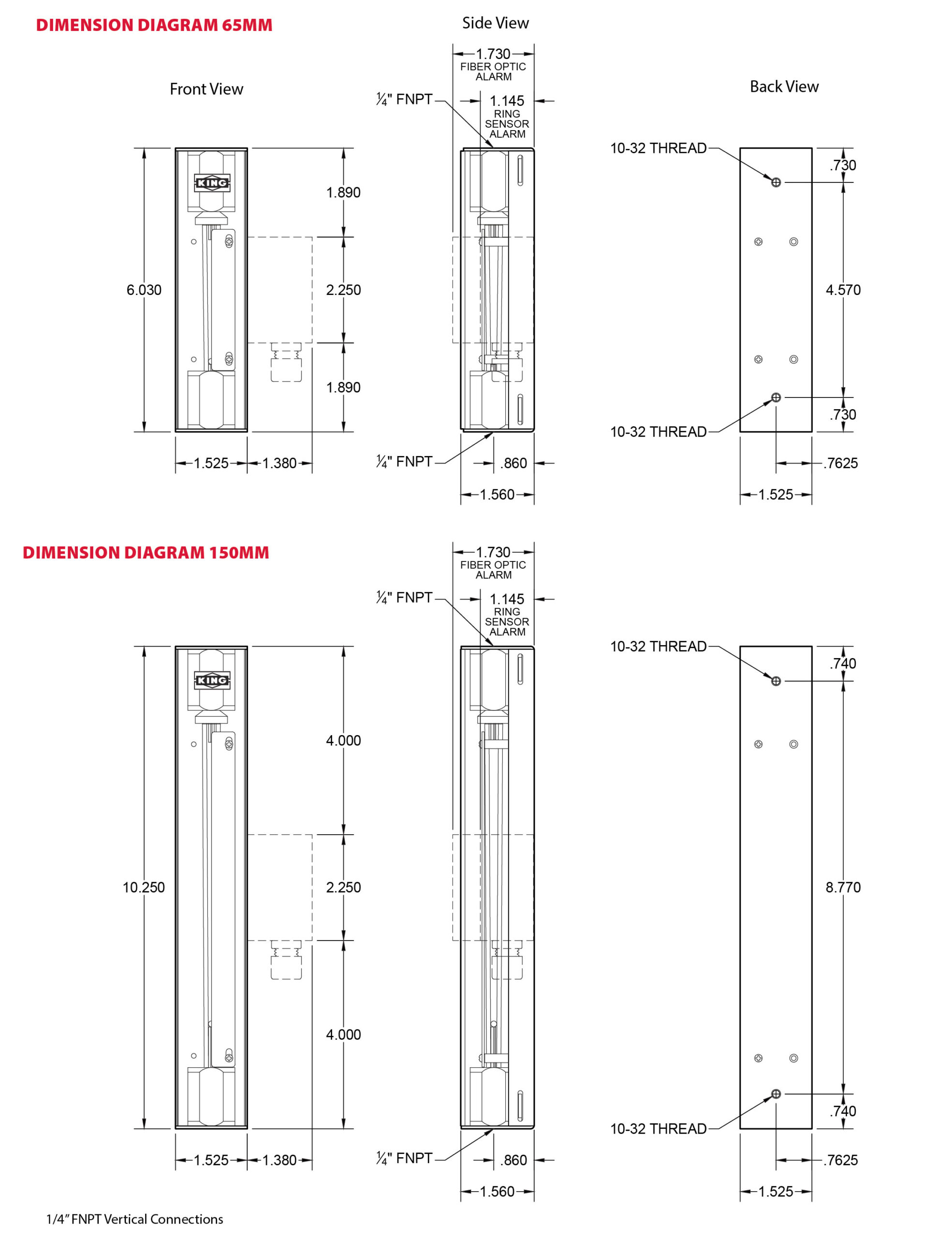

DIMENSIONS (INCHES)

1/4” FNPT Vertical Connections

ALARM OPTIONS:

Inductive Ring Sensor

7440 Series flowmeters with metallic floats can be ordered with an inductive ring sensor that is able to detect a predetermined rate of flow and is compatible with stainless steel or Carboloy floats only.

Inductive ring sensors are 2-wire, DC, low current devices and are designed to be used with a remote intrinsic safety barrier /switch isolator. Sensors are available as either proximity or latching devices. The sensor can be positioned to trigger at any point on the scale. It is able to detect the metal float by producing an electromagnetic field that senses the float within its sensing zone.

The inductive sensor connects to a barrier/switch isolator which powers the sensor and provides the desired switching option. Barrier/switch isolators are available with 220VAC, 110VAC or 24VDC supply voltage requirements, contain single pole double throw (SPDT) relays, and are DIN rail mountable. See barrier/switch isolator specifications for electrical connections and further details.

Maximum operating temperature 40° C for 1/8” float; 70° C for 1/4” float.

Note: We can supply the safety barriers/switch isolators upon request. User must provide the power supply voltage

Fiber Optic Sensor

The fiber optic alarm sensor is an available option for all 7440 Series flowmeters and is compatible with all float materials except sapphire. The sensor is used to detect a predetermined rate of flow. The sensor can interface directly to a Programmable Logic Controller (PLC) or when connected to a separate relay can trigger a local or remote alarm.

The fiber optic sensor is mounted in a junction box attached to the side of the flowmeter. The sensor uses a pair of fiber optic cables, an emitter and receiver, to transmit the light generated by the sensor. Note: Maximum operating temperature 131° F.

ORDERING:

Use the following guide to determine the specific product number you require for the 65mm or the 150mm flowmeter.

Example: 74V - 102G021 - 1 - 2 - 3 - 1 - 0

|

74 |

||||||

| Meter Series |

Tube Number |

Float Material |

Fitting Material |

O-Ring Material |

Scale | Optional Alarm Switch |

|

Std. Temp. High Temp. |

see Specifications table |

Glass - 1 Sapphire - 2 316 SS - 3 Carboloy - 4 Tantalum - 5 |

316L SS 1/4" FNPT - 1 PVDF 1/4" FNPT - 2 |

EPR - 1 Buna-N - 2 Viton® - 3 Kalrez® - 4 |

Millimeter - 1 |

Without Alarm - 0 (1) Fiber Optic switch is not available for sapphire floats |